Runwell specializes in testing of temporary pipe work equipment. This by performing a variety of specific tests in a certified testing environment. With the testing of your equipment, Runwell helps to ensure that the used equipment meets the functional requirements as stated in the API6A international standard and also meets the product standards set by the manufacturer. With periodically inspection, testing and recertification of your equipment, a safe operation is optimally ensured.

Inspection

In addition to our well utilized and certified test environment on the Runwell yard in Schoonebeek, Runwell also possesses the ability to test your Oilfield equipment at customer production sites.

Runwell performs the necessary inspections:

- Visual inspection

- Dimensional verification: controlling measurements and erosion

- NDT crack detection inspection

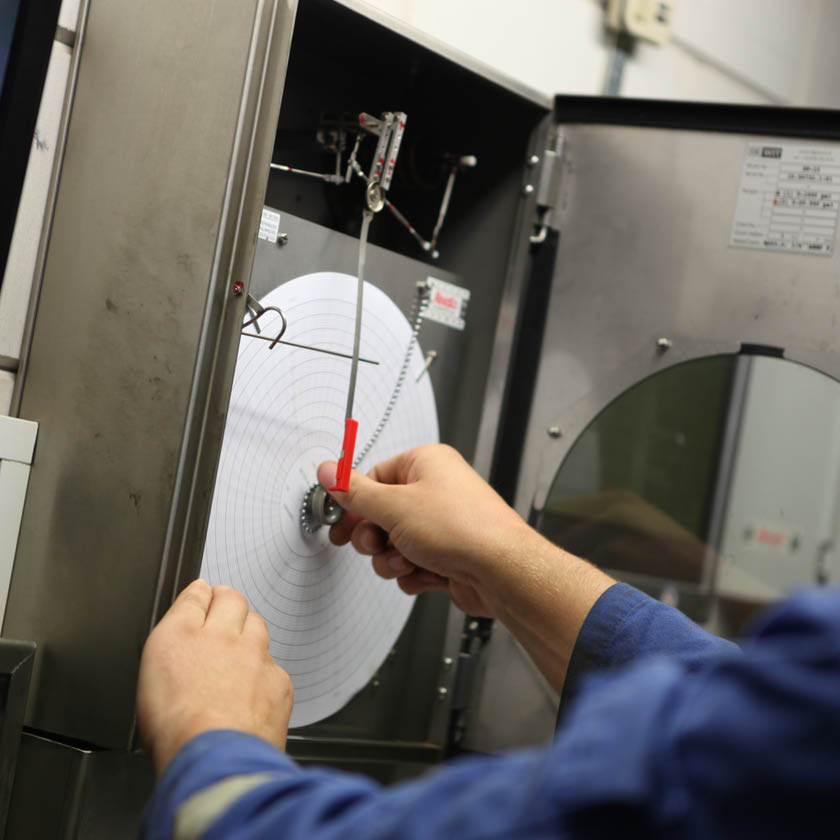

- High Pressure test

Testing

The equipment is tested with the following tests:

- High Pressure Body Test

- High Pressure Function Test

Our test engineers are all qualified and competent to execute the high pressure testing activities. All engineers are in possession of BOSIET, Nogepa, HUET and VCA certificates to operate safely on your production location.

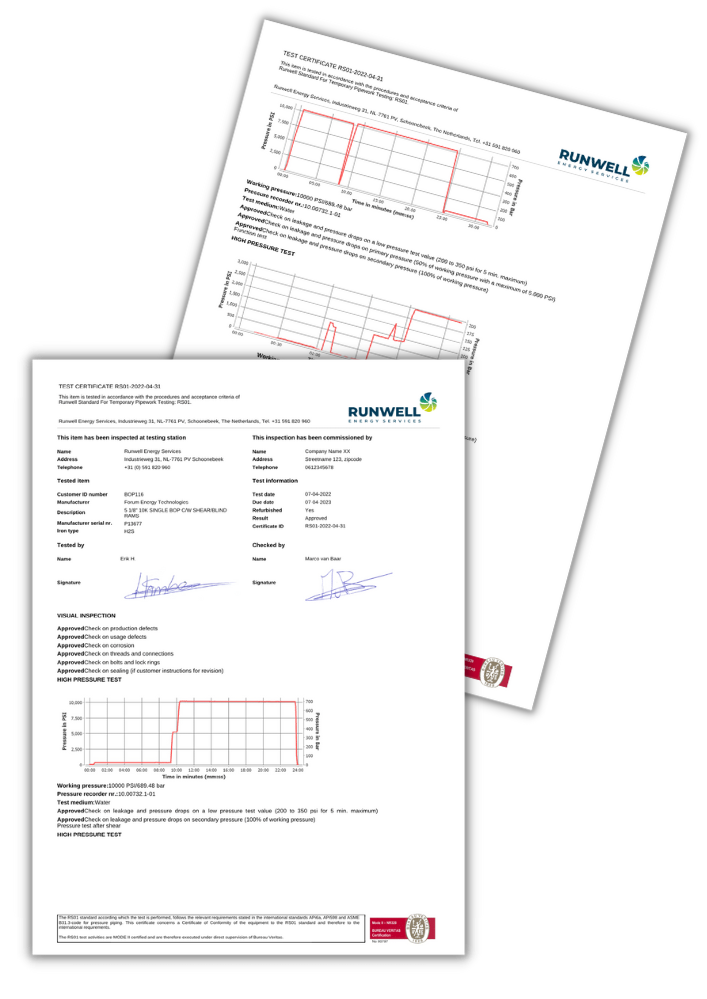

Recertification

With the inspections and tests, Runwell Energy Services is authorized to recertify your equipment based on:

- OEM Specification

- API-6A Conformity

- RS01 Procedure

- Mode II Certification by Bureau Veritas

Our certificates contain:

- All relevant data

- Compliance declaration

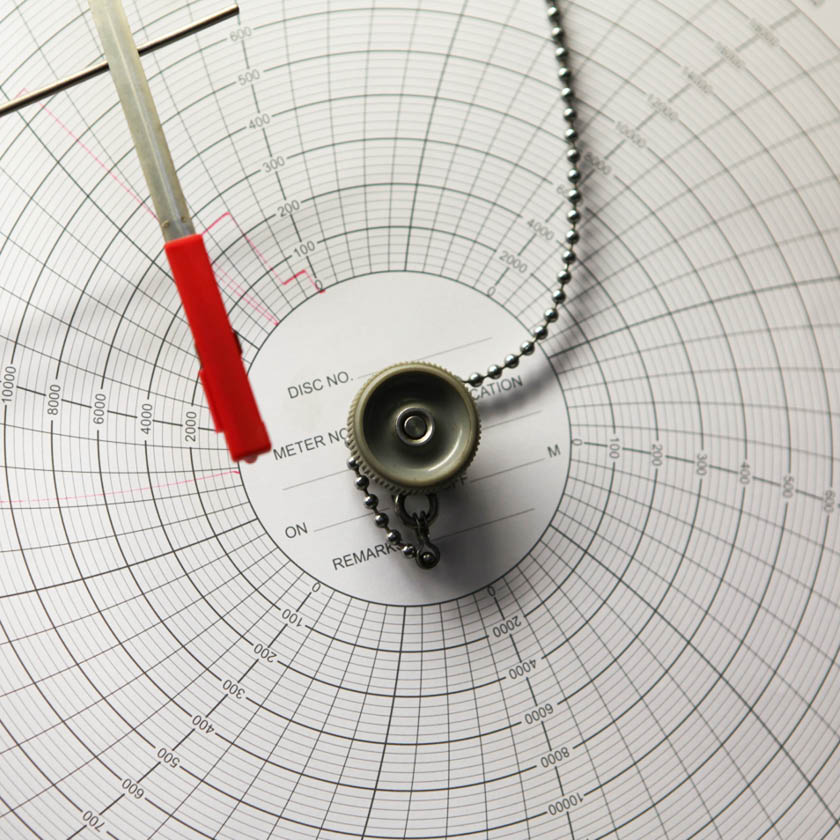

- Graphic high pressure result